An efficient supply chain is the backbone of a product-based economy. A smooth flow of products throughout the supply chain is extremely important to keeping the economy stable. For this, order processing in supply chain management should be stable and on time.

Order processing is a set of sequential steps that a company takes to fulfill a customer’s order. This process involves supply chain management as the products get transferred from the manufacturing unit to the customer’s home.

Righteous order processing is the only solution that can ensure the smooth flow of supply chain operations. Let’s talk about it more in this blog with a comprehensive discussion.

Get it started!

What’s Included in Logistics Order Processing

Order processing is an elaborate concept that includes managing, tracking, and disbursing orders. From initial order placement to final delivery, a smooth order processing system covers everything. With the help of efficient order processing management, your organization can deliver products to customers.

An interesting fact regarding late delivery has come out in a recent study by Voxware. It says that nearly 30% of shoppers are less likely to purchase again from the same online retailer who failed to deliver their products on time. Moreover, the percentage of people agreeing with this phenomenon has been increasing gradually over the years. Meaning that there is no scope for improvement for online retailers other than speeding up the deliveries.

Online retailers are not alone; late delivery of items is a big issue that affects other major industrial operations, too. Late deliveries affect customers’ relationships plus increase costs. However, with the help of quick order processing and efficient order management policies, these issues can be resolved.

Efficient and accurate order processing can ensure on-time order deliveries, which will lead to higher customer satisfaction and enhance supply chain performance.

Now, you need to understand the key components that excellent order processing in supply chain management includes. Let’s get into it.

Components of Order Processing

The supply chain system is like a big threat that covers up everything. From collecting raw materials to delivering finished goods to the last mile, it includes all. Order processing and management play quite a big role in the supply chain process. It has multiple components that allow the flow of products or services from one end to another.

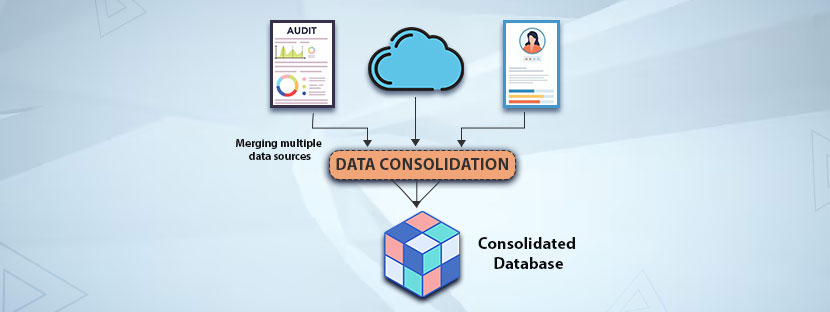

Order Data Capture

Logistics order processing starts with collecting the orders. Logistics companies receive orders from multiple channels. It covers phone, email, e-commerce platforms, websites, and other media. However, the processing of the order will get started only after the contracts are signed.

⏵ Process Orders

Once the contracts are signed, now comes the order processing. This is a detailed process where each of the order details will get verified with respective sources. After order verification, now comes the inventory verification part. Here, the availability of inventory is checked and the data is shared with the agreed suppliers and manufacturers. With the right order processing steps, order tracking, order fulfillment, and other tasks will be processed smoothly.

⏵ Order Fulfillment

This component holds the main part where the main order-related works are getting done. Well, it starts with picking up the products, packing them, and then shipping them to the customer. For each step, respective documents are getting collected and then processed accordingly.

⏵ Order Tracking

Tracking orders and providing customers with real-time updates is the main idea of order tracking. Nowadays, software or tools are used to get the live update of orders.

⏵ Compliant Adjustments

A big part of the order processing in supply chain management works to redress complaints. Handling queries and complaints regarding deliveries and returns is part of this component. The satisfaction level of customers is proportionally related to the complement adjustment. Faster complaint management will lead to an increase in customer satisfaction.

Order Processing Metrics in Logistics or KPIs

Measuring the efficiency and effectiveness of the logistics order processing system is important. For that, we can depend on some vital order processing metrics or key performance indicators (KPIs). Keeping a check on each KPI can make the overall order processing system better and faster.

Here are the most common KPIs or order processing metrics that you need to check;

Order Cycle Time

The total time, starting fromthe order taken from customers till the order gets delivered, comes under the order cycle. A short order cycle indicates an efficient and productive order processing system.

Order Accuracy Rate

Getting an order delivered right the first time without any fixes can be regarded as an order accuracy rate. Processing orders on the first chance always make customers happy. Besides that, a higher order accuracy rate also keeps costs down. Because you would not have to fix things and spend money on them frequently.

Cost per Order

Order processing is a collective process, and it includes various cost factors. Labor costs, overhead charges, cost of materials, and other things are there. You need to always aim to reduce the cost per order because that is the main matter for measuring this KPI. A gradual drop in cost per order is possible when things go right.

Order Fill Rate

Availability of products in the inventory matters the most in logistics order processing. Order fill rate as a KPI indicates the percentage of customer orders that can fulfilled through the available stock. This KPI checks a balance with stock and customer orders.

On-Time Delivery Rate

Delivering orders on time is the main and the most important work for a logistics company. However, ideally, you must deliver the items before the expected date to satisfy your customers more. Therefore, this KPI measures the percentage of orders delivered on or before the expected delivery date.

Customer Return Rate

In logistics order processing, the customer return rate measures the percentage of orders that are returned by customers. If the return rate is high then you have to check the quality of the products.

Backorder Rate

Sometimes due to higher demand, some orders get canceled. Non-availability of the products in stock is the sole reason for that. However, in terms of KPI, this phenomenon is reverted as a backorder rate. You must always target to decrease the backorder rate for better inventory management.

Average Order Value

The number of orders that are delivered on average is taken up by this metric. Revealing the order value in monetary terms provides a clear roadmap for the marketing team to strategize their marketing plan.

First Contact Resolution

Ideally, whenever a customer reaches a compliant redressal department, it should be solved at the first interaction. This KPI is specifically designed to measure the first contact problem resolution.

Customer Satisfaction Score

A higher customer satisfaction score indicates the effectiveness of the order processing system. The customer satisfaction score gets data from post-delivery surveys. It also means you cannot do anything except make your order processing system better and more functional.

Benefits of Effective Order Processing in Supply Chain Management

As discussed before, order processing is the key factor that determines the effectiveness of the supply chain. With quick order processing, you can ensure your orders get delivered on time and satisfy your customers. That’s not the only benefit you can have, but the list of benefits also includes;

Improve Customer Satisfaction

Making customers satisfied with the products is the goal that every business follows. But what if the product did not reach the customer on time? That’s the reason you need an excellent supply chain management system. With that, you can expect to get your products delivered to your customers at the right time.

Big logistics firms invest a huge amount in collecting and processing customer data. Processing customer data helps provide a better customer experience. In logistics, you can get your customers’ data from orders. Providing them with better experience will lead to making them more loyal.

Increase Productivity

The order management process is a comprehensive and elaborative mechanism. With an excellent strategy, it can eliminate redundancies and bottlenecks from the process. Therefore, it will lead to greater productivity and efficiency in the supply chain system.

Better Inventory Management

Smoothly managed orders also increase the chances of making the inventory better. Here’s how;

When you learn how to manage your inventory, you’ll handle your order better. Efficient order processing helps you manage your inventory better.

Improved Supplier Relationships

Effective order processing in supply chain management helps you to maintain good relationships with your suppliers. In logistics, there are multiple suppliers involved; therefore, it’s better to rely on the best techniques of order processing. This is the way you can make better relationships with suppliers

Minimizing order errors or delays can effectively reduce cost factors. With the no-order error state, you do not need to pay the cost of returns, stockouts, excess inventory stand-out time, etc. Overall, it will boost the effectiveness of the system. With time, it will help you enhance financial performance and bring excellence to the supply chain system.

Common Barriers in Order Processing in Logistics

Logistics order processing is a complex deal to take control of. Everything from scratch you need to consider to get the order fulfilled. The most common challenges of order processing you can encounter here are;

Best Practices of order processing in supply chain management

Following up on a standardized process is a must to process orders in logistics efficiently. We will now get some solid ideas or rather the best practices of order processing here. Following each practice diligently can improve your order fulfillment rate and increase customer satisfaction.

Simplify the order processing system.

The more your order processing steps will be, the better you can handle them. Errors and inefficiencies always come when you make the process complex. If order processing is taking up too much time, you can always choose to outsource order processing services for better management of orders. The majority of the top logistics companies do that to manage their bulk order. Outsourcing is simple and yet effective.

Utilize technology whenever possible

Nowadays, various tools are there to manage orders, track them, and process them. You can smartly incorporate the new technology into your system to make order processing smart and effective. The development of AI in logistics is also increasing, and thus, you must give it a try.

The only consideration here is that you must not automate the order processing completely. It’s a fact that AI-enabled software can automate the task, but orders will still remain unfulfilled without human insights. So, you can go for a semi-automated order processing system to get the most out of it.

Establish communication channels with stakeholders.

Communicating with stakeholders is important, and you cannot ignore it. Try to establish open communication with all the stakeholders to avoid any type of confusion. Besides straight communication, you need to take special care whenever any complex issue arises. In that sense, you have to communicate positively to ensure smooth order management and problem resolution.

Follow the Trends of Logistics Orders Management

Keep following the latest trends in order processing in supply chain management. The top leaders of your industry probably implement all the trends in their process instantly. That’s the only reason they landed up in the top position. You need to follow that pattern, too, with the help of this habit. Whenever you spot a new trend in the supply chain, you need to assess and apply it to your system.